Research

Projects

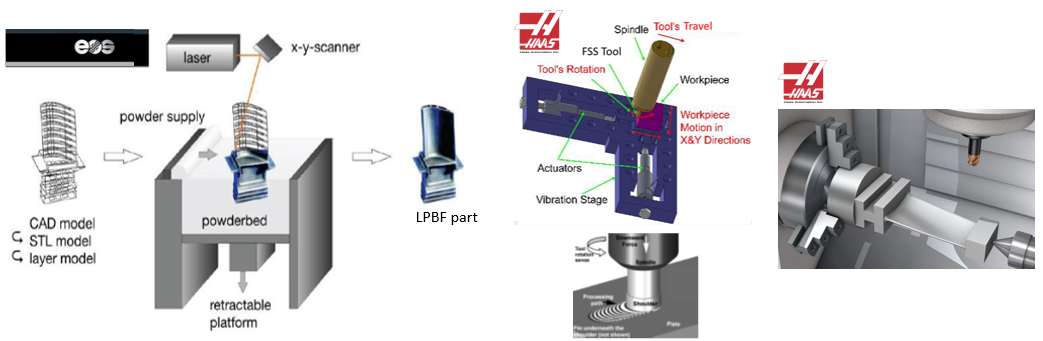

1. Vibration-Assisted Friction Stir Surfacing of Additively Manufactured High-Performance Metallic Alloys (funded by NSF ERI Award No. 2501927)

Metal additive manufacturing technologies such as laser powder bed fusion (LPBF) enable the fabrication of complex, high-performance metallic components but often introduce defects such as porosity, lack of fusion, and high residual stress that degrade fatigue performance. This project investigates Vibration-Assisted Friction Stir Surfacing (VAFSS) as a novel post-processing technique to address these limitations by transforming cast microstructures into wrought-like surface layers, eliminating near-surface defects, reducing residual stress, and enhancing fatigue strength in LPBF-built alloys. Through integrated experiments and modeling, the research establishes fundamental relationships between VAFSS process parameters, surface integrity, and fatigue behavior. The project also supports workforce development through student training, new graduate courses, and outreach activities in additive manufacturing and advanced surface engineering.

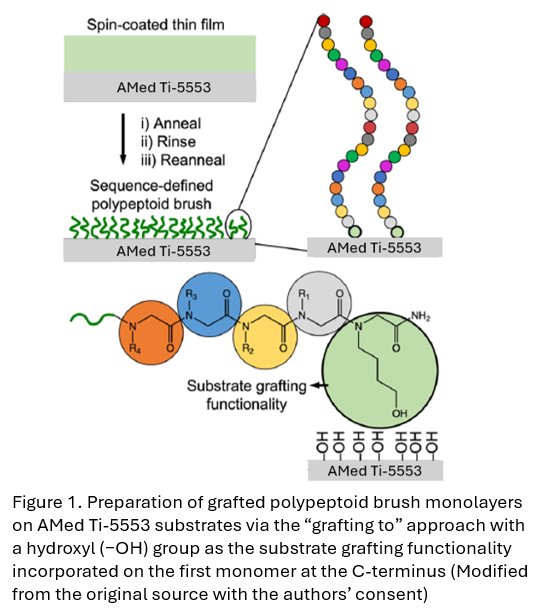

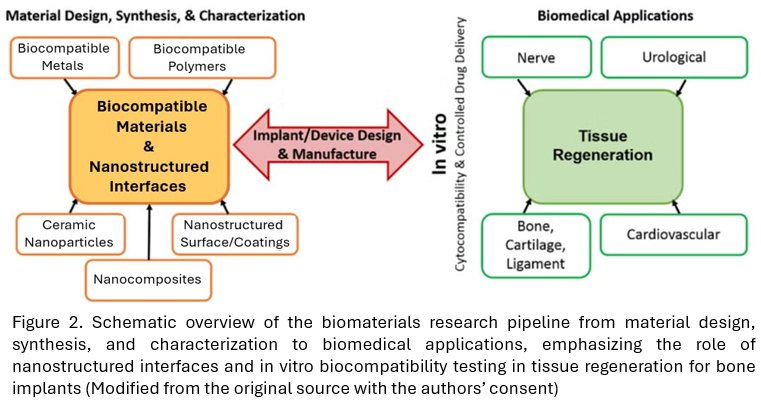

2.Cross-Scale Texturing of Additively Manufactured Ti-5553 Bioimplants for Enhanced Osseointegration (funded by DoE LBNL Proposal No. 10463 & 10708)

This project focuses on developing next-generation orthopedic bioimplants by integrating cross-scale surface texturing and biomimetic functionalization on additively manufactured Ti-5553 alloys. While additive manufacturing enables patient-specific implant geometries, current implant surfaces lack the hierarchical micro- and nano-scale features required for robust osseointegration and infection resistance. By mimicking the multi-scale architecture of natural bone, the research aims to enhance cell adhesion, mechanical interlocking, and bioactive signaling at the implant–tissue interface. Leveraging advanced nanofabrication and characterization capabilities, the project investigates functionalized polypeptoid brush coatings as a tunable biointerface on textured Ti-5553 surfaces. Through systematic control of surface chemistry and in vitro biological evaluation, the work seeks to establish fundamental links between surface topography, interfacial chemistry, and biological response, ultimately advancing biomaterials engineering and enabling durable, infection-resistant, and patient-specific implants with improved clinical performance.

Ongoing and Long-Term Research Areas

- 3D Printing for Electronic Packaging and Interconnection

Additive and hybrid manufacturing approaches for advanced electronic packaging, thermal management, and interconnect reliability. - Hybrid Additive Manufacturing-Machining of Aerospace Alloys and Space Materials

Process-structure-property relationships in hybrid manufacturing of high-performance alloys, with current emphasis on Ti-5553. - Friction Stir Welding and Processing at Macro- and Micro-Scales

Solid-state joining and processing of dissimilar and advanced materials, including aluminum alloys and bulk metallic glasses (BMGs). - Surface Integrity and Microstructure Evolution in Hybrid Micro-Machining of Bulk Metallic

Glasses

Investigation of surface integrity, subsurface damage, and microstructural evolution during precision and micro-scale machining of BMGs.

Fabrication Equipment

EOS M 100 Direct Metal Laser Sintering system (funder by NSF MRI Award No. 1920363)

EOS GmbH Electro Optical Systems

HAAS CNC Mill (TM-1)

HAAS CNC Lathe (ST-10)

Sponsors

National Science Foundation

Department of Energy

Lawrence Berkeley National Laboratory

SJSU, College of Engineering

SJSU, Division of Research & Innovation

Characterization Facilities

Available from: